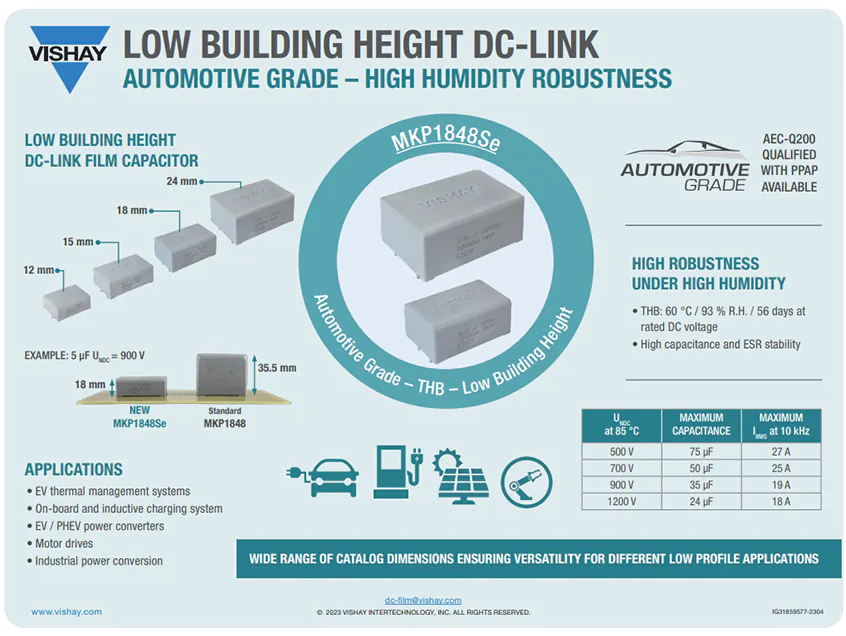

Vishay, the MKP1848Se series is qualified for automotive use. Applicable on EV/HEV power converters, from OBC to DC/DC converters and copmpressors, whenever space availability is limited.

APPLICATIONS:

EV/PHEV(plugin hybrid electric vehicle) power converters;

On-board and inductive charging systems;

Automobile HVAC systems;

Motor drives

What is film capacitors?

Film capacitors, plastic film capacitors, film dielectric capacitors, or polymer film capacitors, generically called film caps as well as power film capacitors, are electrical capacitors with an insulating plastic film as the dielectric, sometimes combined with paper as carrier of the elctrodes.

Film capacitors for use in electronic equipment are packaged in the common and usual industry styles: axial, radial, and SMD. Traditional axial type packages are less used today, but are still specified for point-to-point wiring and some traditional through-hole printed circuit boards. The most common form factor is the radial type (single ended), with both terminals on one side of the capacitor body. To facilitate automated insertion, radial plastic film capacitors are commonly constructed with terminal spacings at standardized distances, starting with 2.5 mm pitch and increasing in 2.5 mm steps. Radial capacitors are available potted in plastic cases, or dipped in an epoxy resin to protect the capacitor body against environmental influences. Although the transient heat of reflow soldering induces high stress in the plastic film materials, film capacitors able to withstand such temperatures are available in surface-mounted device (SMD) packages.

ADVANTAGES:

Polypropylene film capacitors can qualify for Class 1 applications

Very low dissipation factors (tan δ), high quality factors (Q) and low inductance values (ESL)

No microphonics compared with ceramic capacitors

Metallized construction has self-healing properties

High rated voltages, up to the range of kV possible

Much higher ripple current, compared with electrolytic capacitors

Much lower aging, compared with electrolytic capacitors of similar values

High and very high surge current pulses possible

DISADVANTAGES:

Larger physical size compared to electrolytic capacitors

Limited number of types in surface-mount technology (SMT) packaging

Film/foil types have no self-healing capability (irreversible short circuit)

Possibly flammable under overload conditions

https://www.mouser.com/new/vishay/vishay-metallized-polypropylene-film-capacitors/